How To Calculate Machine Operator Efficiency

PlantRun systems can be used to measure track and analyse individual operator performance and compare the performance of machine operators against timemachineproduct etc. Machines are meant to.

What Is Oee And How Does It Work Evocon

Labor hours per acre are based on field capacity of machinery.

How to calculate machine operator efficiency. OPERATOR EFFICIENCY FORMULA OE CALCULATION OPERATOR EFFICIENCY IN PRODUCTIONMachine operator efficiency MOE is a lean manufacturing term used to desc. Chemistry questions and answers. 2- If the efficiency of the previous machine was 50 How much did the machine convert the electrical energy into mechanical kinetic energy.

Operator workers. This is generally measured through direct means like measuring the total electricity input into a system but it can also be calculate. Overhead costs paid to the machine operator.

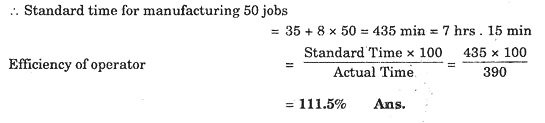

The operators efficiency is measured as the time spent producing product divided by the time the operator is on duty. Lets take a look at an example of how you can calculate efficiency. Improper maintenance of machines will result in low standards of produced parts and increases the maintenance of machines.

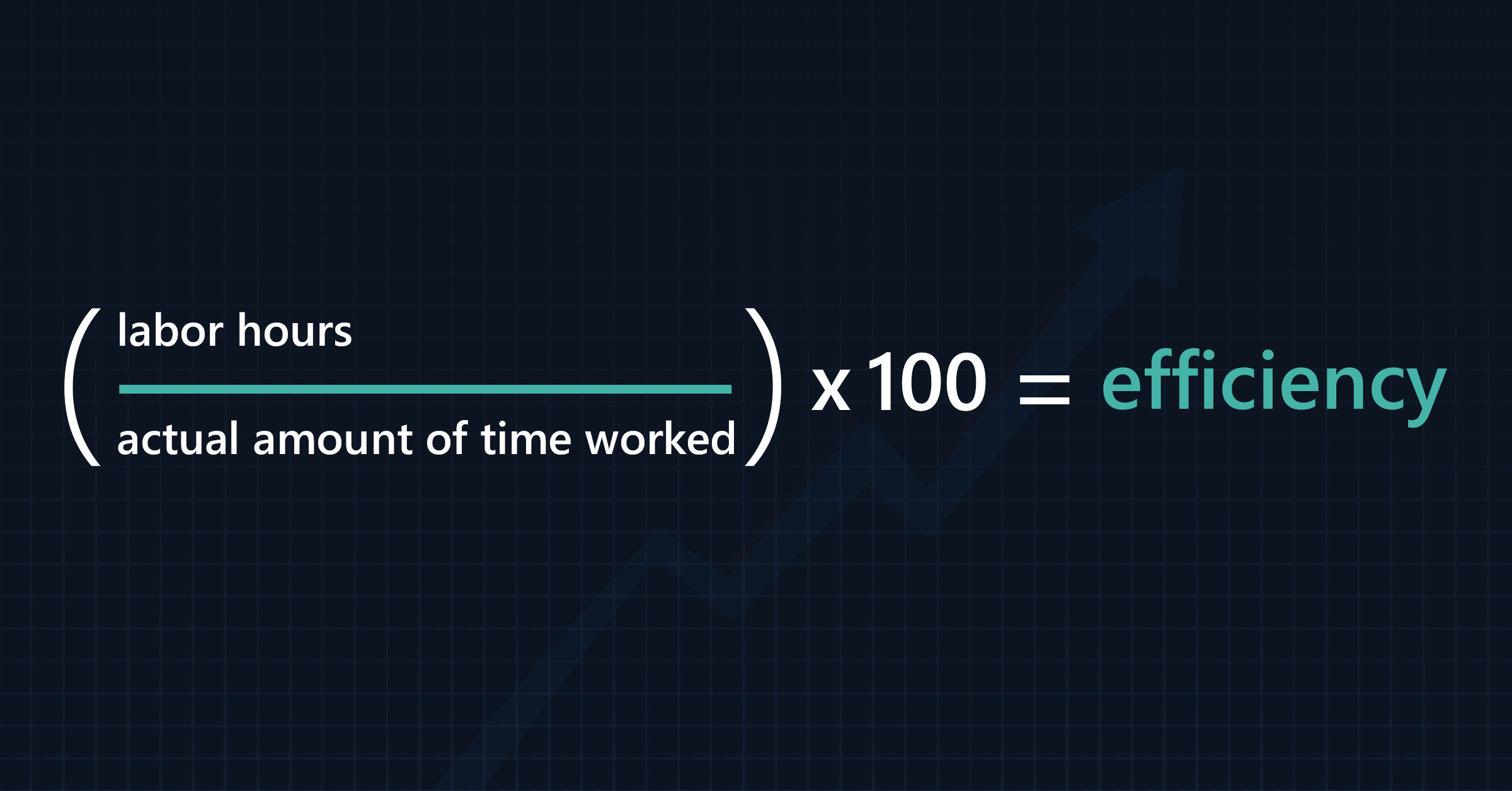

Efficiency Total minute produced by an operatorTotal minute attended by him 100 Where Total minutes produced Total pieces made by an operator X SAM of the operation minutes Total minutes attended Total hours worked on the machine X 60 minutes. If an operator is assigned to run a CNC machine tool for seven hours but they only have four hours worth of continuous uninterrupted output of workpiecestheir MOE rating is 57 4 divided by 7 for this seven-hour period of time. Savings 1- O1M1M2 O1M1O2M2 100.

Productivity OutputInput This basic productivity formula can be used to calculate the productivity of your complete production process or of a particular process or machine within your production process. Efficiency Total minute created by an operatorTotal minute attended by him 100 Where Total minutes created Total items created by an operator X SAM of the operation minutes Total minutes attended Total hours worked on the machine. We use the following formula for calculating efficiency.

Machine efficiency is one of the factors that are frequently overlooked by the management and this can lead towards losses which reduces the yield 1 2. Measuring and improving operator efficiency of machines and equipment on the shopfloor can have a dramatic effect on manufacturing productivity and output. The first step is to calculate or measure the energy being input into a system.

Output must be expressed as a numerical value and is the finished value of goods or services produced by a person machine or process. Efficiency Total minutes produced X 100 Total hours worked X 60 In the above formula 60 is multiplied to convert hours into minutes and 100 is multiplied to express in percentage. Even for ideal applications there is a limit to how much money a company can expect to save by having one operator run two machines.

PlantRun can then provide you with machine operator efficiency in real-time or over any period as operator OEE MOE. Efficiency calculation formula. You can identify the operators with best and worst performance.

The next step is to calculate the total work output. A simple formula can be used to determine this savings. Labor costacres completedhour wage rate per.

Use the following formula and calculate operator efficiency. Built in tools allow reporting based on operator efficiency and analysis of operator performance against product batch shift or downtime. A labor adjustment factor is used to calculate total labor hours for machinery operation including time for locating hooking up adjusting and transporting machinery.

1- Calculate the efficiency of a machine whose electric motor consumes 960 joules of electrical energy to generate 335 joules of mechanical mechanical movement. Measuring and improving operator efficiency of machines and equipment on the shopfloor can have a dramatic effect on manufacturing productivity and outputPl.

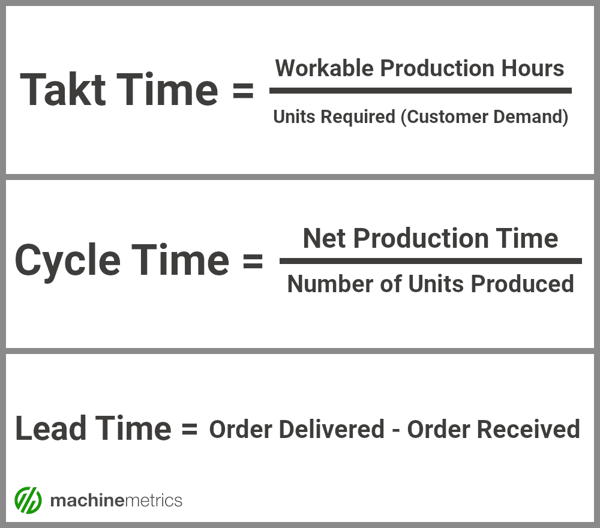

Takt Time Vs Cycle Time Vs Lead Time Definitions And Calculations

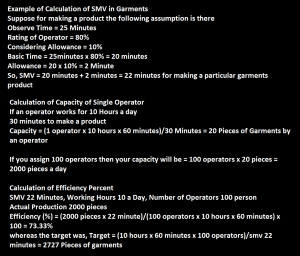

Standard Minute Value Smv In Garments Calculation Importance Ordnur

How To Calculate Overall Line Efficiency

Calculating Productivity And Efficiency At The Workplace By Alexander Pavlov Medium

Efficiency Formula Calculate Operator Efficiency And Line Efficiency

A More Accurate Way To Calculate The Cost Of Electricity

How To Calculate Overall Line Efficiency

Standard Minute Value Smv Definition Calculation And Use

What Is Line Balancing And How To Achieve It Tulip

Oee Factors Understand Availability Performance Quality Oee

Time Study Definition Procedure And Methods

How To Calculate Overall Line Efficiency

Production Line Efficiency Report Format And Formula Download Template

What Is Oee And How Does It Work Evocon

Increase Manufacturing Production Capacity Vorne

Standard Minute Value Smv In Garments Calculation Importance Ordnur

What Is Line Balancing And How To Achieve It Tulip

Efficiency Calculation Formula Formula Critical Thinking Efficiency

Post a Comment for "How To Calculate Machine Operator Efficiency"