Calculate Machine Utilization Percentage

Calculate how many hours the employee actually works on client work. MEM 100- freebufferscached100TotalMemory.

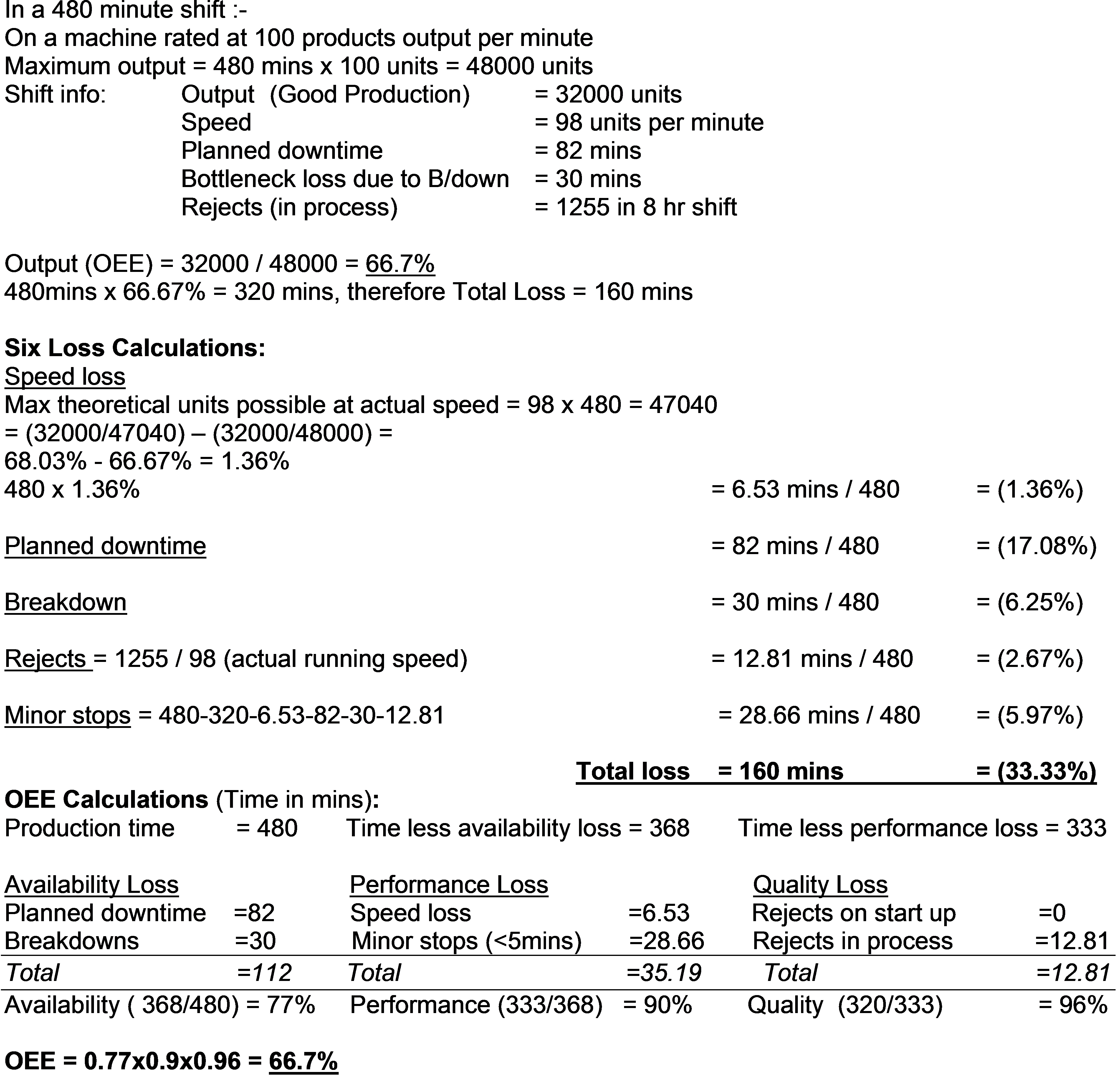

Here is a simple example based on a manufacturing operation with a 65 OEE score that is running two 8-hour shifts per day five days per week.

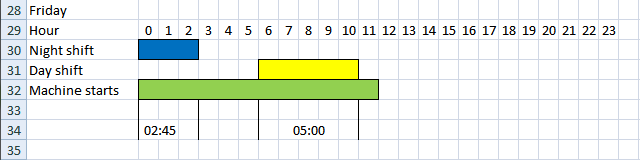

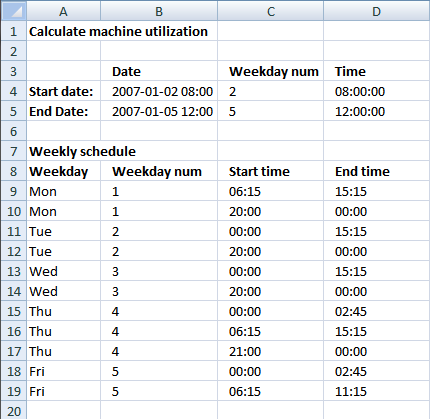

Calculate machine utilization percentage. SUMPRODUCTCOUNTIFSC4 B9B18 D4 C9C18 D4. The capacity utilization rate is 1400 over 1600 or 875 percent. For example if 32 hours of billable time are recorded in a fixed 40-hour week the utilization rate would then be 32 40 80.

Available time for production ideal production rate 100. Capacity Utilization is the rate at which potential output levels are being met or used. In a smallmedium sized manufacturing plant we do not have the luxury to run fully integrated CRMMRP system.

By using the formula of capacity utilization rate we can calculate Capacity Utilization Rate Actual outputMaximum possible output100. This can easily be tracked with time log. Ideal rate is based on cycle time ie the total denominator gives value which is how much you have to achieve the production for the available time.

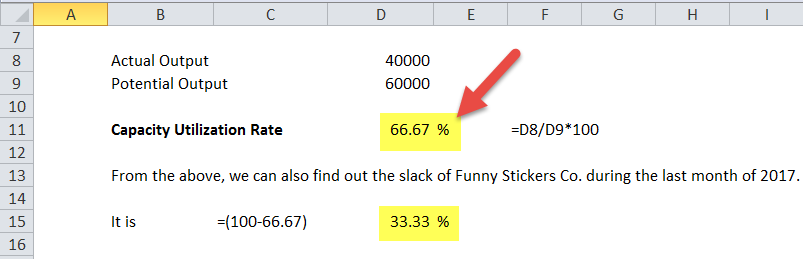

We have one metric known as uptime where in it is equal to. Thus Im using the formula I have now. From the above we can also find out the slack of XYZ company during the last financial year of 2016.

Capacity Utilization Rate 6000080000. Subtract the total servicerepair hours of Step 3 from the total availability hours of Step 2. Utilization Planned Production Time All Time.

To calculate a utilization rate follow these steps. For example say that a business has the capacity to produce 1600 widgets a day as in the above example but is only producing 1400. By using the formula of capacity utilization we get Capacity Utilization Actual Output Potential Output 100.

How to Calculate Capacity Utilization Capacity Utilization Actual outputMaximum possible output100. 5 Steps To Calculate Machine Utilization Rates One month ago I was assigned to calculate and present the Machine Utilization Rates of all the plastic injection machines in our production plant. The capacity utilization rate cannot exceed beyond 100 as no machine or human can be expected to work to a full capacity of 100 the maximum capacity utilization rate that can be expected is of 90 as there can be many problems that can arise both with the man and the machine.

I need a script to calculate memory percentage no matter what the flavour of OS it is. Production achieved. Hi all Can anybody tell me how to calculate machine utilization.

The second way to calculate the utilization rate is to take the number of billable hours and divide by a fixed number of hours per week. Calculate the number of hours an employee is on the clock during a standard week. From the above we can also find out the slack of Funny Stickers Co.

Capacity Utilization Rate 75. TEEP OEE Utilization. TEEP is calculated as.

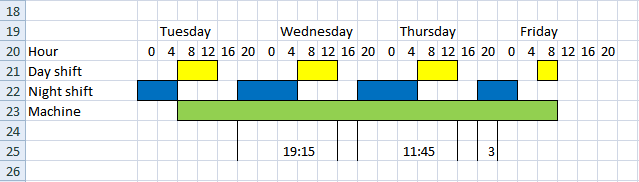

I have tried calculating memory from top command grep Mem but it is very arbitrary. Calculate utilized machine hours Array formula in cell D21. It essentially tracks how much of a manufacturers production capacity is currently being utilized.

The formula for capacity-utilization rate is actual output divided by the potential output. Slack 100 75. For instance if the shift length is 10 hours and the servicerepair time per shift averages one hour the total availability of that piece of machinery is 9 hours or 90 percent.

During the last month of 2017. Utilization is calculated as. Or Capacity Utilization 40000 60000 100 6667.

![]()

Calculate Teep Measure Utilization And Capacity Oee

Capacity Utilization Rate Definition Formula How To Calculate

Oee Overall Equipment Effectiveness

How To Calculate Oee For Multiple Machines Industrial Training

Capacity Utilization Definition Example And Economic Significance

Oee Overall Equipment Effectiveness

Machine Utilization Analysis And Report

How Utilization Rate Affects Your Profitability How To Increase It

Calculating Throughput Throughput Analysis Part I

Calculate Teep Measure Utilization And Capacity Oee

Oee Overall Equipment Effectiveness

Capacity Utilization Manufacturing Kpi Examples Sisense

Capacity Utilization Rate Formula Calculation With Examples Youtube

Calculate Teep Measure Utilization And Capacity Oee

Do You Know The Utilization Of Your Rental Fleet Karmak

Capacity Utilization Rate Definition Formula How To Calculate

Post a Comment for "Calculate Machine Utilization Percentage"