Machine Utilization Operations Management

Its a simple measurement that has powerful effects on how your business runs. When it comes to resource management utilization rates help in forecasting resource optimization and many other essential business functions.

Strategic Capacity Planning Introduction To Operations Management

To determine the utilization of machines and overall equipment effectiveness of machine shop by analyzing the data obtained.

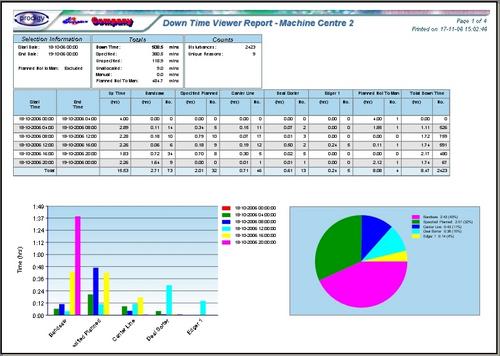

Machine utilization operations management. These charts are also of value is studying maintenance jobs where work-loads are varied and uneven and where several products and machines are to be attended by one operator. Machine M 2 utilization time 2646 100 56. Average loads on all machine types N 30 Average loads on all machine types N 70 Average loads on all machine types N 100.

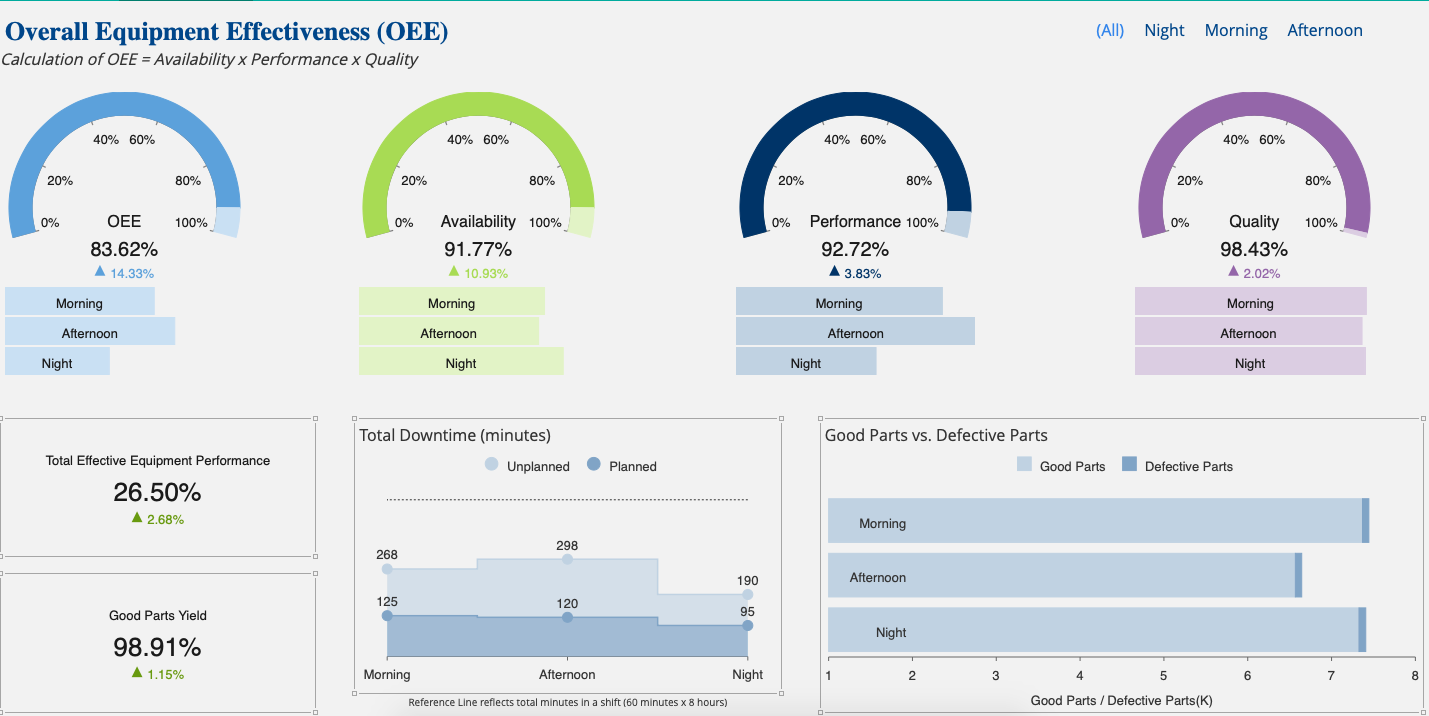

Under utilization of various manufacturing units due to number of non-productive activities which in turn decreases the Overall Equipment Effectiveness OEE. Average loads on critical machine types N IVk for critical operations N 70 Vik for critical operations N 100. The manager will take into account each machines operating costs and initial costs and its breakdown and repair times.

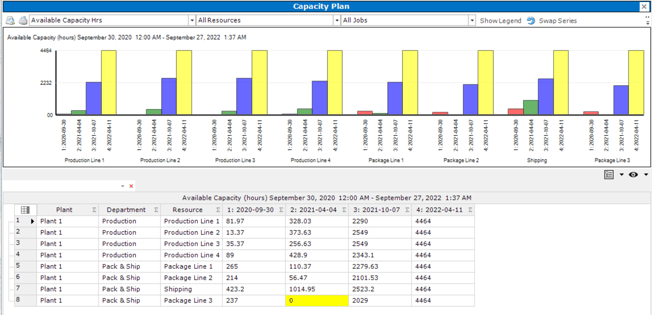

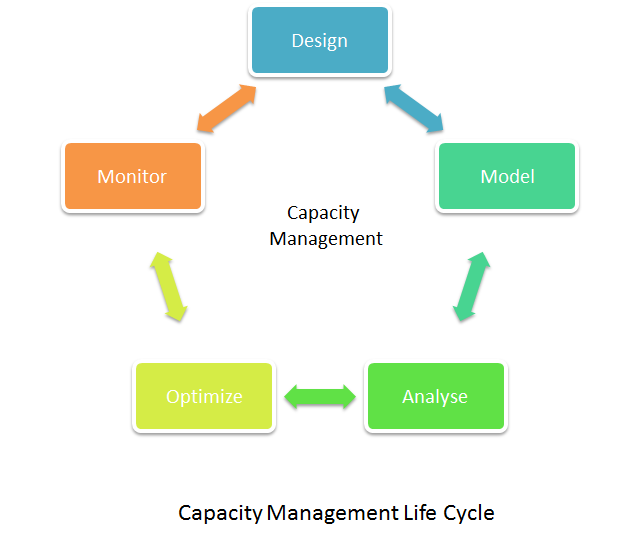

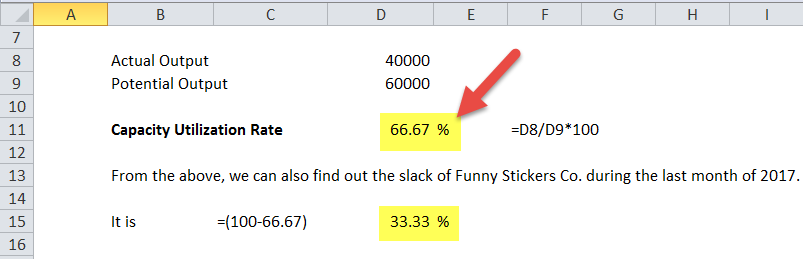

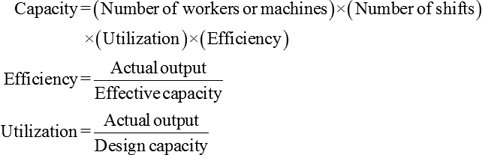

Operations management is concerned essentially with the utilization of resources ie obtaining maximum effect from resources or minimizing their loss under utilization or waste. No utilization records prior to 2010 4 excavators 2011-2013 2874 hrsyrAvg 8 excavators 2014-2016 5590 hrsyrAvg Doubled number of machines as well as total annual machine hours since 2013 work Approximately 10 increase in annual utilization. Capacity utilization rate is a metric which is used to compute the rate at which probable output levels are being met or used.

A manager must decide between two machines. The utilization always lies between 0 and 100. Operations managers have to understand the utility of machine material man information and energy.

Capacity utilization rate is also called as operating rate. It can be used as a measure which helps determine optimum timing of capacity. The output is displayed as a percentage and it can give a proper insight into the general negligence that the organization is at a point of time.

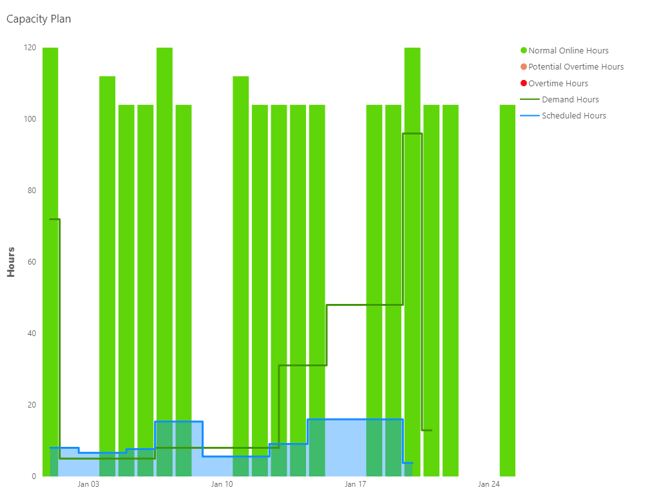

The idea was that equipment was expensive and should be fully utilized. The y-axis has a fixed scale of 0 to 120. A traditional approach to Operations Management revolved around keeping the machines busy.

Product - Customer requirements and approval of the design in the form of prototype. If V-CPU Utilization is greater than 120 then the point is plotted as 120 and the detail displayed when you place the cursor on the point shows the actual value. Capacity Utilization Capacity utilized or gross production Optimum capacity or production level The use of capacity utilization as a KPI Capacity utilization is a widely used KPI and operational measure in many industries in the strategic capacity and business planning functions of many organizations.

They have to assess the rationality of each of these resources or entities in their role in the operations system they are running. It is calculated as flow rate divided by capacity eg. Accountants encouraged this as well believing the more the machine was running the more the cost of the machine could be absorbed.

Vk for critical operations N 200. Capacity utilization is calculated by. Machine A has a projected average operating time of 126 hours and a projected average repair time of 5 hours.

The utilization tells us how well a resource is being used. Machine M 1 utilization time 2846 100 6130. The V-CPU utilization is computed using the raw data shown on the V-CPUs Used chart.

Capacity Analysis In Operations Management

Capacity Utilization Rate Definition Formula How To Calculate

Oee Vs Ope Teep What Should Manufacturers Calculate

What Is Capacity Management Definition And Faqs Omnisci

Calculate Teep Measure Utilization And Capacity Oee

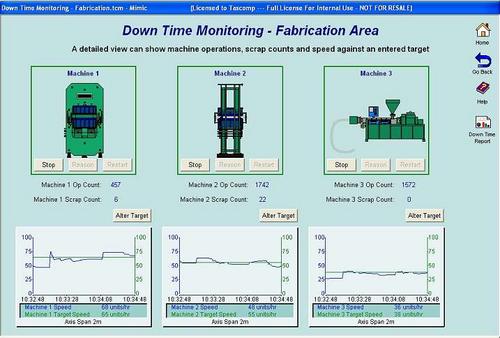

Machine Downtime Machine Utilization And Downtime Systems

Machine Downtime Machine Utilization And Downtime Systems

Visualizing Oee To Monitor Productivity Wyn Enterprise

Advantages Of Cellular Manufacturing

Capacity Utilization Rate Definition Formula How To Calculate

Real Time Machine Utilization Dashboards Utilization Reporting Machinemetrics Real Time Machine Dashboards Dashboard Reports

Capacity Utilization Manufacturing Kpi Examples Sisense

Strategic Capacity Planning Introduction To Operations Management

Virtualization And Virtual Machine Vm Capacity Planner Tool Solarwinds

Capacity Utilization Rate Formula Calculation With Examples Youtube

Capacity Analysis In Operations Management

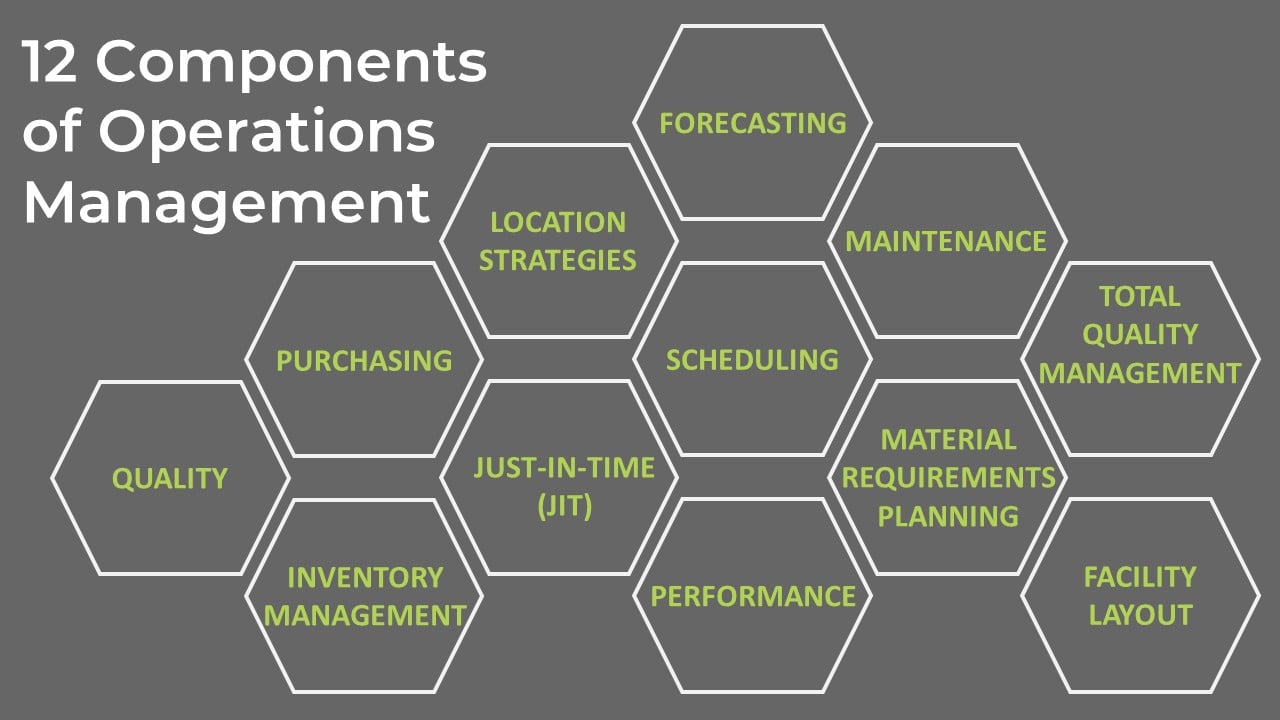

12 Components Of Operations Management

Definition Of Capacity Planning Chegg Com

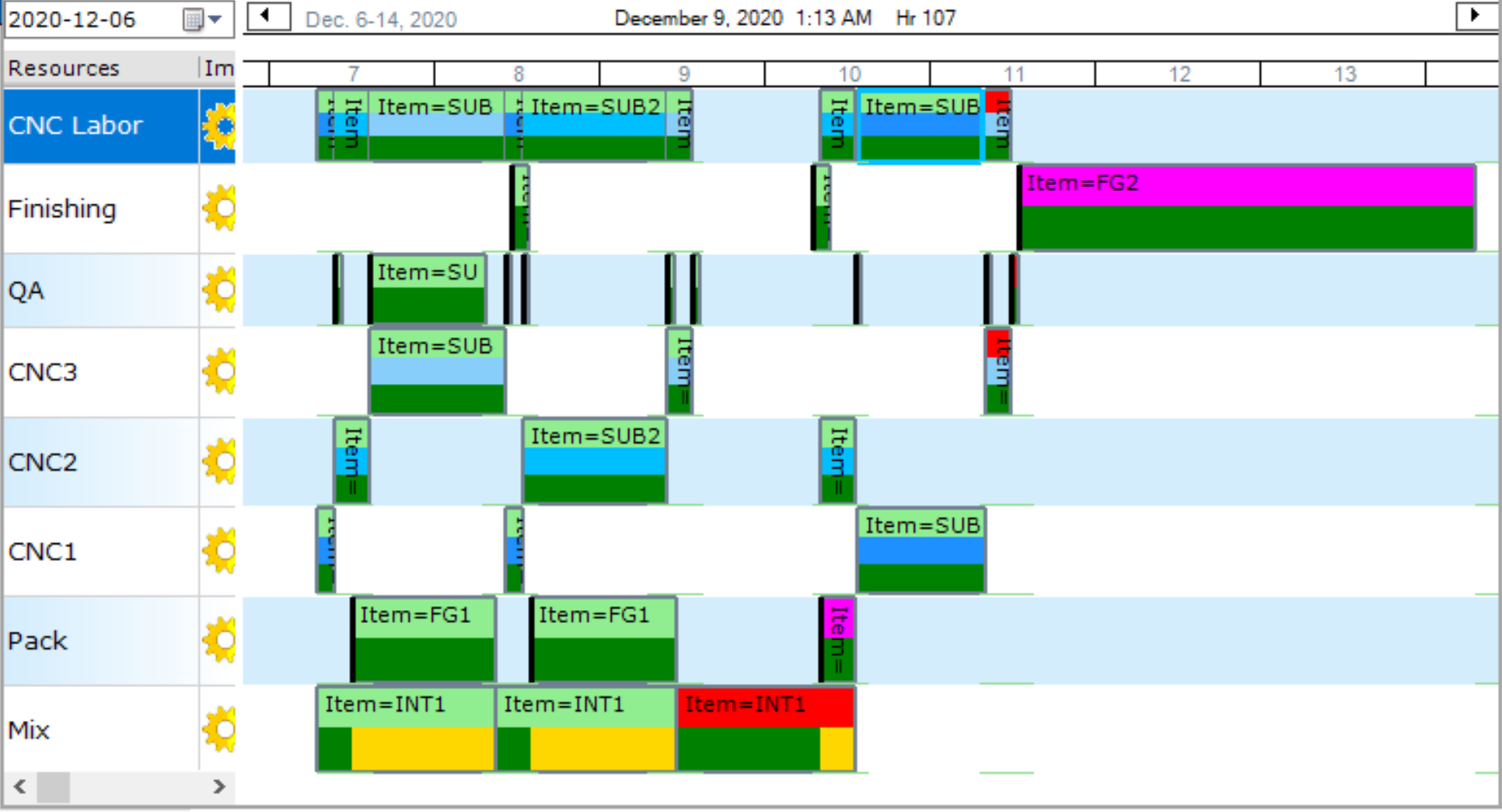

Gantt Charts As A Tool For Production Planning And Control

Post a Comment for "Machine Utilization Operations Management"