Automated Machine Vision Based System For Fruit Sorting And Grading

With the increased demand in high and good quality of agricultural. In the present study a machine vision based online sorting system was developed the aim being to sort Date fruits Berhee CV based at different stages of maturity namely Khalal Rotab and Tamar to meet consumers demands.

The Fruit Piano Or Any Makey Makey Like Project Explained And Arduino Code Provided Musicmonday Stem Projects Cool Writing Arduino

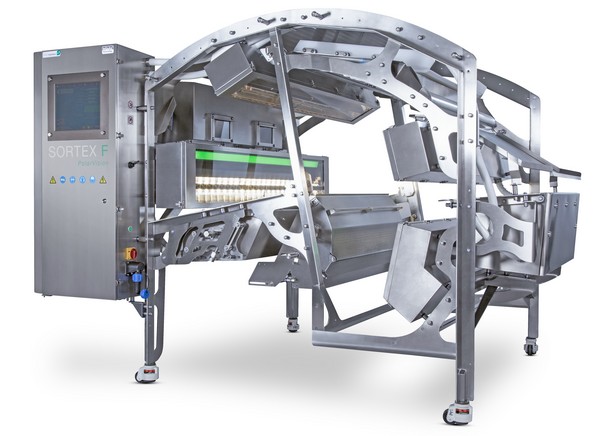

A combination of rigorous image processing algorithms and robust hardware ensures that each fruit is scrutinized comprehensively for all defects before exiting the inspection line.

Automated machine vision based system for fruit sorting and grading. Machine vision applications used for robot assistance. The manual inspection poses problems in maintaining consistency in grading and uniformity in sorting. RSIP Vision has successfully worked in number of date sorting or date grading projects for our clients.

Machine fruit sorting is an important process in the field of precision agriculture as it enables to automatically classify produce before it is marketed. The application of machine vision based system aimed to replace manual based technique for grading and sorting of fruit. Multiple Fruit and Vegetable Fruit Sorting System using Machine Vision is presented in this paper.

So it has mechanical electrical electronics and software parts. In recent years researchers had developed numerous algorithms for fruit sorting using computer vision. An automatic electronic vision based system for sorting and grading of fruit like Mango Mangifera indica L based on their maturity level and size is discussed here.

Robotics and Machine Vision systems for Electronics industry - High Speed inspection system AGVs Box Erectors and Barcode Reading system Automatic Fruit Grading and Sorting System IndiaVision based Sorting system India Fruit Sorting System India - Automatic Grading System India. 3 presented a computer vision based system for automatic grading and sorting of based on maturity level of the agricultural products like mango. FruiTron is an innovation that automates the task of sorting fruits with higher accuracy and greater throughput.

The grading systems were developed for easing the labor intensive work and create consistency in the quality of the product. In order to increase the strawberry values and found the applied quickly and nicety algorithm the automated strawberry grading system has been set up by using machine-vision technology. The application of automatic vision based system aimed to replace manual based technique for sorting and grading of fruit as the manual inspection poses problems in maintaining consistency in grading and uniformity in sorting.

Chandra Sekhar et al. So by adding more features like fruit. The machine vision based systems have been used in many applications requiring visual inspection of fruits such as apple dates mango citrus and pears.

The system comprises a conveying unit illumination and capturing unit and sorting unit. To develop an automatic fruit sorting and grading machine system which can sort the fruit based on the quality of it 7. Color textural and morphological features are the most commonly used to identify the diseases maturity and class of the fruits.

The current grading systems involved in the fruit sorting cater to only one type of fruit. Machine vision based system aimed to replacemanual based technique for grading and sorting of fruit with the strength of great accurateness and correctness exactness and also provides high processing speed. Speed and accurate sorting can be achieved with machine vision assisted sorting.

The paper presents a computer vision based system for automatic grading and sorting of agricultural products like Mango Mangifera indica L based on maturity level. Hence there is a need of an intelligent fruit grading system. Methodology Sorting systems for different four food products oranges lemons tomatoes and gooseberries are developed.

The quality of the apples is determined according to the colour weight dimension and their defects. The attributes of the individual products are calculated using Gaussian Mixture Model for automatic grading and sorting. 1 The automated strawberry grading system was completed and divided into a mechanical part an image processing part and a control part.

In any automatic apple sorting system mainly consists of machine vision conveyor band separator and classifier. For grading of mango pixel value is considered Computer vision and image processing techniques have been found increasingly useful in the fruit industry especially for applications in quality inspection and defect sorting.

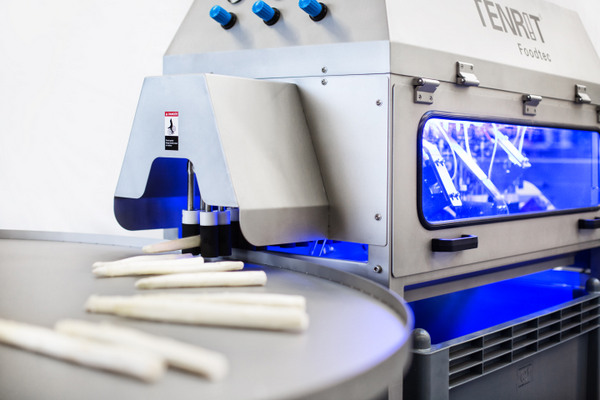

You Can No Longer Do Without An Asparagus Peeling Machine

Celebrating Three Years Of Sortex Fa Polarvision

You Can No Longer Do Without An Asparagus Peeling Machine

With This Bell Pepper De Coring Machine We Re Focusing On The High Middle Segment

Harvester Makes Sort Work In The Orchard Good Fruit Grower

Washing And Drying Line For Leafy Vegetables Veggieline Deployed For Mise En Place

Deep Learning And Machine Vision For Food Processing A Survey Sciencedirect

Robotic Harvester Plucks An Apple Every 7 Seconds

Robotic Harvester Plucks An Apple Every 7 Seconds

Industrial Conveyors System Conveyor System Conveyors Crates

You Can No Longer Do Without An Asparagus Peeling Machine

You Can No Longer Do Without An Asparagus Peeling Machine

Potato Grader Potato Size Sorting Machine Youtube Size Sorting Machine Sorting

Post a Comment for "Automated Machine Vision Based System For Fruit Sorting And Grading"